Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

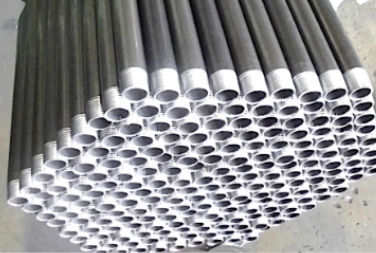

Oxygen Lancing Tube

Oxygen is used in the manufacture of metals like steel, copper and zinc. Chlorine is used in the manufacture of Aluminium. These gases react with the undesirable impurities and form their respective oxide or chlorides. These oxides or chlorides then float to the surface of the molten metal and are removed.

To transfer these gases to the molten metal, a pipe is needed. This pipe is the lancing pipe and the process of injecting gases into molten metal is known as lancing.

Traditionally an ordinary pipe has been used. The material of construction is low carbon steel (Mild Steel), electrically resistance welded (ERW) in the shape of a pipe. Since the molten is steel or copper or zinc, and the pipe is of mild steel, the pipe melts into molten metal, at the end which is dipped into it. Besides because of high temperature of the molten metal, the pipe also gets oxidized and melts faster into the molten metal. Hence the pipe gets consumed and has to be replaced.

The following sizes are available when it comes to lancing tubes.

OD WT Length (Meters) End type

5.0mm 1.0mm 1.2 or 3 Plain

6.0mm 1.0mm 1.2 or 3 Plain

8.0mm 1.0mm 5.5 or 6 Plain

10.0mm 1.0mm 5.5 or 6 Plain

12.0mm 1.5mm 5.5 or 6 Threaded

13.2mm 1.8mm 5.5 or 6 Threaded

17.2mm 1.8mm 5.5 or 6 Threaded

21.3mm 2.0mm 5.5 or 6 Threaded

Thermic Lance Pipe

Thermic Lance Pipe is a steel pipe filled with wires or a mixture of wires and an inner pipe, when burning generates a powerful flame up to 4,000°C without noise and vibration to break up materials quickly. Generally, the metal tube contains steel wire that promotes combustion.

There are lots of processes in steel production by Electric Furnace including Electric Arc Furnaces. Initially, the first process in Electric Arc Furnace is to cut large size scraps as material preparation then put scraps in the Electric Arc Furnace. With this purpose, customers look for the oxygen lance pipe that are to be used for fusing the metals and so on. Therefore, Thermic Lance is one optimal option since the principle is that harness the oxidation heat of high temperature by providing the pressurized oxygen inside an ignited steel tube.

Calorized Lance Pipe

The lance pipes used for blowing oxygen, carbon and other materials into electric furnaces must be tough and resistant to heat and oxidation. And so the usage of Calorized lance pipes can reduce the number of lance pipes used, leading to cost savings and safe operations.

CA Lance (CA) Pipe lasts 3 to 10 times longer than mild steel lances and is used not only for the melting and refining of steel by blowing oxygen gas, but also used for the injection of carbon, lime, and/or other additives.

The next process of steel production is to open the tap hole so that the production process will get enough flow of the melted iron. With this purpose, most of manufacturers tend to choose SC Lance pipes.

SC Lance Pipe

SC Lance (SC) is a mild steel oxygen lance pipe made with HRC (Hot Rolled Steel Sheet in the coil), welded by high-frequency welding equipment, there is no oil, and no grease on the pipe.

After pouring out liquid steel, the workers will use SC Lance pipe to clean stuck metal inside the converter after a long time using. The SC Lance pipe is called to be used overhere once again for the cleaning furnace purpose.

SC LANCE generates a high temperature of over 3,000℃ by blowing oxygen and melting solidified steel, and slag on equipment. The pipe can be used to remove slag on the wall of the ingot case, pig iron at the iron notch of the blast furnace; clean slag in ladle and steel-slag mixture at the slag notch and iron notch of a Eletrci Arc Furnace, and cut steel scraps.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.