Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

Globe Valve

Globe Valves are extensively used through-out the hydrocarbon, energy and process & the power industries.

Size: ½” up to 24“ (DN 15 up to DN 600)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconel, Titanium Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay

Design Standard: API 602, MESC SPE 77 / 103, BS 1873 DIN 3356

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 598, API 6D, MESC 77/103, ISO 5208, ISO15848 -1&2, BS 6364

Construction Details: Bolted Bonnet / Pressure Seal Bonnet, OS & Y Type Rising Stem

End Connection: Screwed, Socket Weld, Flanged, Hub End, Butt-Weld

Operator / Actuator: Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Globe Valves are available in three different types:

• Bolted Bonnet

• Pressure seal

• Bellows Seal

Cryogenic Service

Globe Valves can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C. If required by the customer, specific Cryogenic Tests are performed to verify the behaviour of production valves in terms of valve torque, sealing capability, emissions vs the ambient.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.

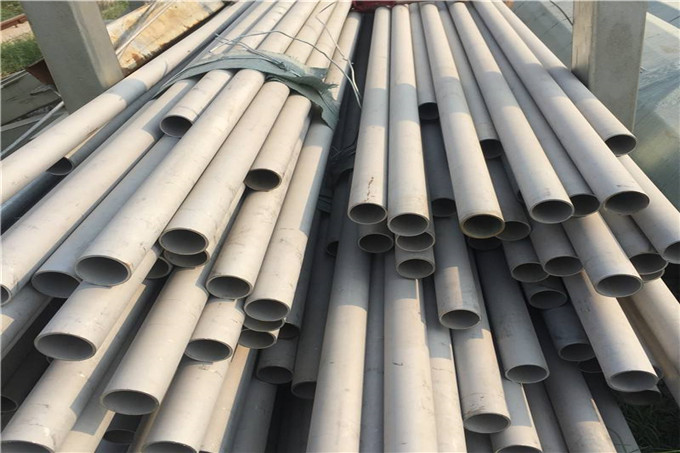

ASTM A270 Sanitary Stainless Steel Tube

it is the standard specification for the welded seamless, and heavily cold worked welded austenitic and ferritic stainless steel sanitary tubing

ASTM A554 Stainless Steel Tube

it covers welded austenitic, ferritic, and austenitic-ferritic duplex stainless steel mechanical tubing intended for use in ornamental, structural, exhaust, and other applications where appearance, mechanical properties, or corrosion resistance is needed.

ASTM A269 Stainless Steel Tube

it is used for low temperature and high temperature services

AISI 405 1.4002 S40500 SUS405 Stainless Steel Pipe Tube

it is a ferritic stainless steel formulated for primary forming into wrought products.