Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

Double Layer Wear Resistant Straight Pipe for Concrete Pump Truck

Dual-layer wear-resistant straight pipeline

Two layers, heterogeneous segmentation of the inner layer and outer layer.

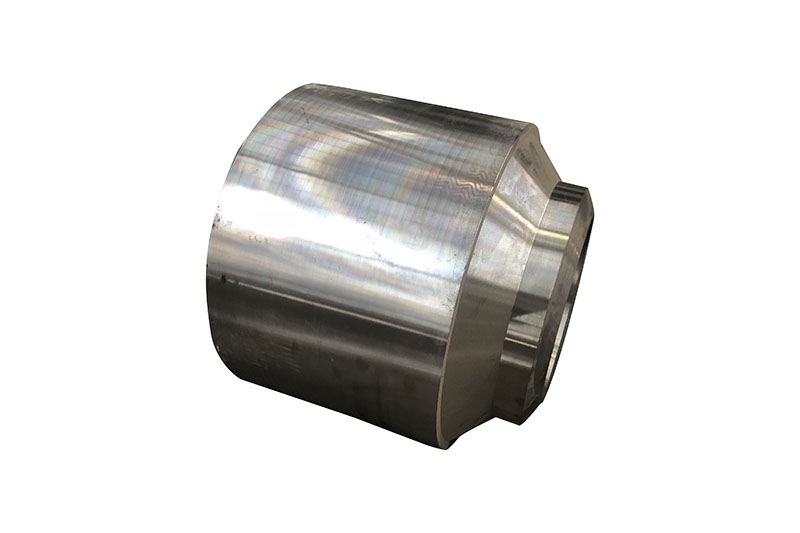

High chromium cast iron wear-resistant casing (3 or multiple casings at the mouth end, symmetrical at both ends), theouter surface of the wear-resistant casing is coated with a composite bowl joint;

Bearing steel 52100 material is used as the inner tube, with a hardness of HRC63-65;

The outer tube is made of E345 seamless pipe, with high strength and toughness after special treatment. The inner wall of the outer tube is reinforced with six reinforcing ribs and positioned for composite assembly.

Wear law of straight pipelines.

According to research and analysis, the wear of the straight pipeline of concrete pump trucks is mainly manifested in the large wear at the end, especially at the flange welding position,which results in large wear and quick failure.

Technological innovation of straight pipelines

Structural innovation

▲ Special structural design with two layers, with the inner layer heterogeneously segmented to precisely reinforce vulnerable areas.

▲ Strengthening at the end and segmented assembly of the pipe body.

Material matching

▲ The inner layer material is divided into end material and pipe body material. Depending on the different wear, acombination of high-chromium cast iron and bearing steel is used.

▲ The outer layer is made of E345 seamless pipe, which has high strength and strong pressure bearing capacity after heat treatment.

Technical characteristics of straight pipelines.

Precise reinforcement of vulnerable areas

▲ By adjusting the structure, the wear-resistant material at the end is changed to improve its wear resistance performance. At the same time, it can withstand high-temperature welding without affecting its wear resistance;

▲ The length of the strengthening area is determined according to the degree of wear in the wear area.

Self-developed core processes

▲ Solve major technical problems in welding and forming processes forbearing steel;

▲ Optimize the heat treatment process for the inner and outer tubes, achieving high hardness for the inner tube and high strength and toughness for the outer tube;

▲ Composite assembly, with special adhesive bonding used for the joint and wear-resistant sleeve of the pipeline.

Real-time detection of key parameters

▲ The entire heat treatment process is automated with intelligent control, ensuring stable and reliable quality;

▲ The multi-stage structure enables full inspection of the inner tube hardness, cracks, roundness, etc;

▲ The finished product is hydrotested at a pressure of 17MPa according to industry standards, with no leakage.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.