Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

Double Layer Wear Resistant Elbow for Concrete Pump Truck

Outer protective layer

According to the wear situation at the end, both ends of the elbow are designed with a 35mm long thickened wear-resistant casing made of high chromium cast iron with a hardness of over HRC62.

Inner Wear-resistant Layer

Regarding the wear analysis of the elbow, this part of the elbow undergoes the most severe wear and the greatest impact force, which is the first area to fail. To address this, uneven thickness is used, gradually increasing from both ends towards the middle, and gradually increasing from both sides towards the middle.

According to the situation of little wear on the inner side of the elbow, a 6mm wear-resistant layer is used for the lower half of the elbow.

The wear law of elbows

The function of elbows is to change the flow direction of the concrete, so the impact and wear force on the outer arc surface of the elbow is the greatest, especially at the end of the elbow, which is subjected to the greatest impact force and fails the fastest.

Technological innovation of elbows.

Structural innovation: dual-layer,split structure, gradual thickening from both ends and sides towards the middle to address wear on the outer arc surface.

Material matching: high-carbon and high-toughness high chromium cast iron is used for the easily worn outer arc, while cost-effective bearing steel is used for the inner arc.

Process innovation: multiple processes are used, such as casting for the outer arc and die forging for the inner ball, and combination welding.

Precise reinforcement of vulnerable areas

▲Improved wear resistance of materials invulnerable areas.

▲Different thickness design of wear-resistant layer invulnerable areas.

Wear-resistant material matching

▲Developed a high-carbon, high-chromium, high-toughness cast iron through collaboration with peers and universities, with excellent wear resistance, impact resistance, high toughness, and strength.

▲Cost-effective bearing steel material is used for the wear-resistant layer of the inner arc, which is formed by die forging.

Multiple process combinations

▲Multiple process combinations achieve mass production of parts with reduced costs.

▲Casting is used for the inner liner of the outer arc , and molding is used for the outer layer; Double-layer integral die forging and integral quenching are used for the inner arc. The precision of the inner and outer arcs is guaranteed by special machine tools, and automatic welding machines are used for welding.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

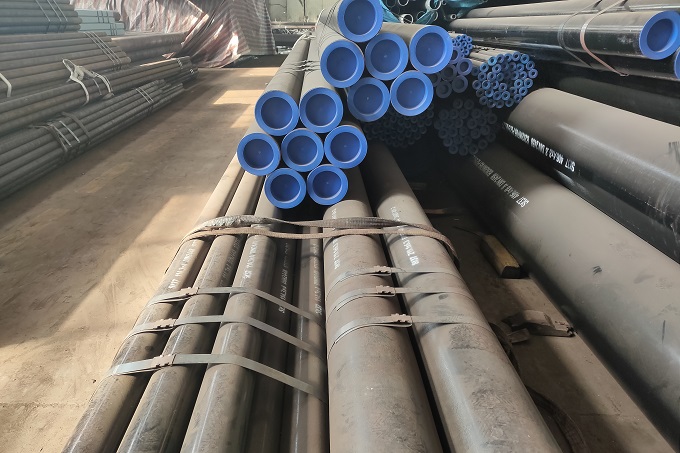

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.

10305-1 Cold Drawn Seamless Steel Tube

EN 10305-1:2016 This European Standard specifies the technical delivery conditions for seamless ...

BS 6323-4 Cold Finished Seamless Steel Tube

Typical BS 6323 Part 4 1982 CFS3 BK Properties; Minimum Yield: 360 N/mm2; Minimum ...