Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

ASTM A516 & ASME SA516 Carbon Steel for Moderate Lower Temperature

The ASME SA516 specification is part of the ASME Boiler & Pressure Vessel Code (BPVC) and is a standard which governs the use of carbon steel in weldable industrial boilers and pressure vessels.

The specification sets standards for pressure vessel and boiler quality steel in moderate and lower temperature service. Steel grades which come under this specification are recognised for certain characteristics which include excellent notch toughness and weldability. The material grades vary in performance and such performance is dictated in part by the steels chemical composition.

HIC tested pressure vessel steel is commonly found in sour gas applications and is particularly suitable for the fabrication of pressure equipment where wet H2S can be a problem due to the long term presence of hydrogen sulphide. Other post production tests can be performed on ASME SA516 either at the mill or by a third party testing house.

ASME SA516 Grade 60

An ideal steel for use in moderate to lower working temperatures, ASME SA516 Grade 60 is used in the fabrication of weldable industrial boilers and steel pressure vessels.

It is a normalized steel which is known for its excellent notch toughness and weldability and is primarily found in pressurised service throughout the oil, gas and petrochemical industry.

Table 1: Chemical Composition of ASME SA516 Grade 60

| Carbon (C) | % |

| 12.5mm or less

12.5 – 50mm 50 – 100mm 100 – 200mm > 200mm |

0.21

0.23 0.25 0.27 0.27 |

| Manganese (Mn) | % |

| 12.5mm or less

• Heat Analysis : • Product Analysis : Over 12.5mm • Heat Analysis : • Product Analysis : |

0.60-0.90

0.55-0.98 0.85-1.20 0.79-1.30 |

| Phosphorus (P) | % |

| (max) | 0.035 |

| Sulphur (S) | % |

| (max) | 0.035 |

| Silicon (Si) | % |

| • Heat Analysis :

• Product Analysis : |

0.15-0.40

0.13-0.45 |

(Maximum values unless stated otherwise)

Table 2: Mechanical Properties of ASME SA516 Grade 60

| DESCRIPTION | GRADE 60 |

| Tensile strength (ksi) | 60-80 |

| Tensile strength (MPa) | 415-550 |

| Yield strength (ksi) | 32 |

| Yield strength (MPa) | 220 |

| Elongation in 200mm (min)(%) | 21 |

| Elongation in 50mm (min) (%) | 25 |

(Minimum values unless stated otherwise)

(Please note: the technical information above is for guidance only – for exact specifications please check with our Sales Team)

ASME SA516 Grade 65

Suitable for a variety of applications in the Petrochemical, Chemical, Oil & Gas Industries, ASME SA516 Grade 65 is a carbon steel used by worldwide fabricators serving these markets.

The steel grade is used in the fabrication of weldable pressure vessels and boilers due to the materials specific composition and characteristics. Excellent notch toughness coupled with good weldability are consistent typical in this grade.

Table 1: Chemical Composition of ASME SA516 Grade 65

| Carbon (C) | % |

| 12.5mm or less

12.5 – 50mm 50 – 100mm 100 – 200mm > 200mm |

0.24

0.26 0.28 0.29 0.29 |

| Manganese (Mn) | % |

| 12.5mm or less

• Heat Analysis : • Product Analysis : Over 12.5mm • Heat Analysis : • Product Analysis : |

0.85-1.20

0.79-1.30 0.85-1.20 0.79-1.30 |

| Phosphorus (P) | % |

| (max) | 0.035 |

| Sulphur (S) | % |

| (max) | 0.035 |

| Silicon (Si) | % |

| • Heat Analysis :

• Product Analysis : |

0.15-0.40

0.13-0.45 |

(Maximum values unless stated otherwise)

Table 2: Mechanical Properties of ASME SA516 Grade 65

| DESCRIPTION | GRADE 65 |

| Tensile strength (ksi) | 65-85 |

| Tensile strength (MPa) | 450-585 |

| Yield strength (ksi) | 35 |

| Yield strength (MPa) | 240 |

| Elongation in 200mm (min)(%) | 19 |

| Elongation in 50mm (min) (%) | 23 |

(Minimum values unless stated otherwise)

(Please note: the technical information above is for guidance only – for exact specifications please check with our Sales Team)

ASME SA516 Grade 70

ASME SA516 Grade 70 – one Masteel’s most popular steel grades, the material is highly sort after for welded fabrication in industrial pressure vessels and boilers.

Used throughout the oil, gas and petrochemical industry the material is a normalized steel with excellent weldability and improved notch toughness i.e. the materials ability to absorb energy when a flaw is present.

We keep this material in stock with added stringent restrictions applied to the chemical, mechanical and testing requirements – this ensures that the material is available to you from our warehouse, regardless of your requirements.

Table 1: Chemical Composition of ASME SA516 Grade 70

| Carbon (C) | % |

| 12.5mm or less

12.5 – 50mm 50 – 100mm 100 – 200mm > 200mm |

0.27

0.28 0.30 0.31 0.31 |

| Manganese (Mn) | % |

| 12.5mm or less

• Heat Analysis : • Product Analysis : Over 12.5mm • Heat Analysis : • Product Analysis : |

0.85-1.20

0.79-1.30 0.85-1.20 0.79-1.30 |

| Phosphorus (P) | % |

| (max) | 0.035 |

| Sulphur (S) | % |

| (max) | 0.035 |

| Silicon (Si) | % |

| • Heat Analysis :

• Product Analysis : |

0.15-0.40

0.13-0.45 |

(Maximum values unless stated otherwise)

Table 2: Mechanical Properties of ASME SA516 Grade 70

| DESCRIPTION | GRADE 70 |

| Tensile strength (ksi) | 70-90 |

| Tensile strength (MPa) | 485-620 |

| Yield strength (ksi) | 38 |

| Yield strength (MPa) | 260 |

| Elongation in 200mm (min)(%) | 17 |

| Elongation in 50mm (min) (%) | 21 |

(Minimum values unless stated otherwise)

(Please note: the technical information above is for guidance only – for exact specifications please check with our Sales Team)

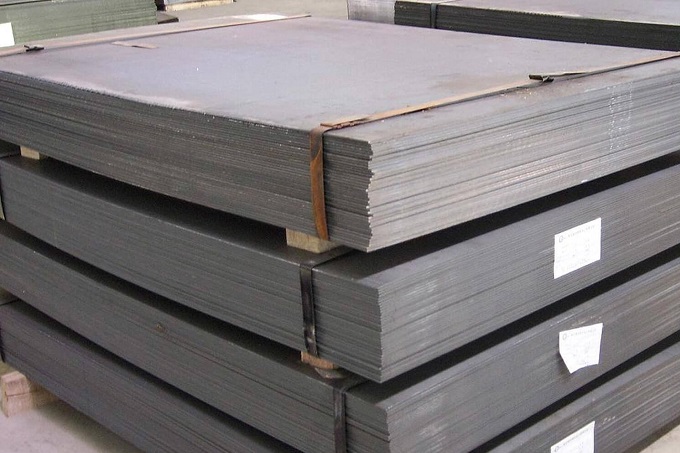

Chemical Composition of Boiler Steel Plates / Sheets

| C | Mn | P max | S max | Si max | ||||||

| t < 12.5

mm |

12.5mm < t =50mm | 50mm < t ≤ 100mm | 100mm < t ≤ 200mm | t < 200

mm |

t < 12.5

mm |

t 12s.5

mm |

||||

| A516 Grade 55 | 0.18 | 0.2 | 0.22 | 0.24 | 0.26 | 06-09 | 0.55-0.98 | 0.035 | 0.035 | 0.15-0.4 |

| A516 Grade 60 | 0.21 | 0.23 | 0.25 | 0.27 | 0.27 | 06-09 | 0.85-1.2 | 0.035 | 0.035 | 0.15-0.4 |

| A516 Grade 65 | 0.24 | 0.26 | 0.28 | 0.29 | 0.29 | 0.85-1.2 | 0.85-1.2 | 0.035 | 0.035 | 0.15-0.4 |

| A516 Grade 70 | 0.27 | 0.28 | 0.3 | 0.31 | 0.31 | 0.85-1.2 | 0.85-1.2 | 0.035 | 0.035 | 0.15-0.4 |

Mechanical Properties Of Boiler Steel Plates & Sheets

| Tensile Strength (ksi) | Tensile Strength (MPa) | Yield Strength (ksi) | Yield Strength (MPa) | Elongation in 200mm(%) | Elongation in 50mm(%) | |

| A516 Grade 55 | 55-75 | 380-515 | 30 | 205 | 23 | 27 |

| A516 Grade 60 | 60-80 | 415-550 | 32 | 220 | 21 | 25 |

| A516 Grade 65 | 65-85 | 450-585 | 35 | 240 | 19 | 23 |

| A516 Grade 70 | 70-90 | 485-620 | 38 | 260 | 17 | 21 |

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

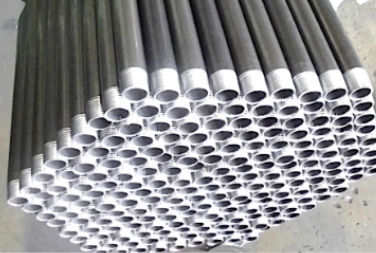

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.

Oxygen Lancing Tube

To transfer these gases to the molten metal, a pipe is needed. This pipe is the lancing pipe and the process of injecting gases into molten metal is known as lancing.