Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

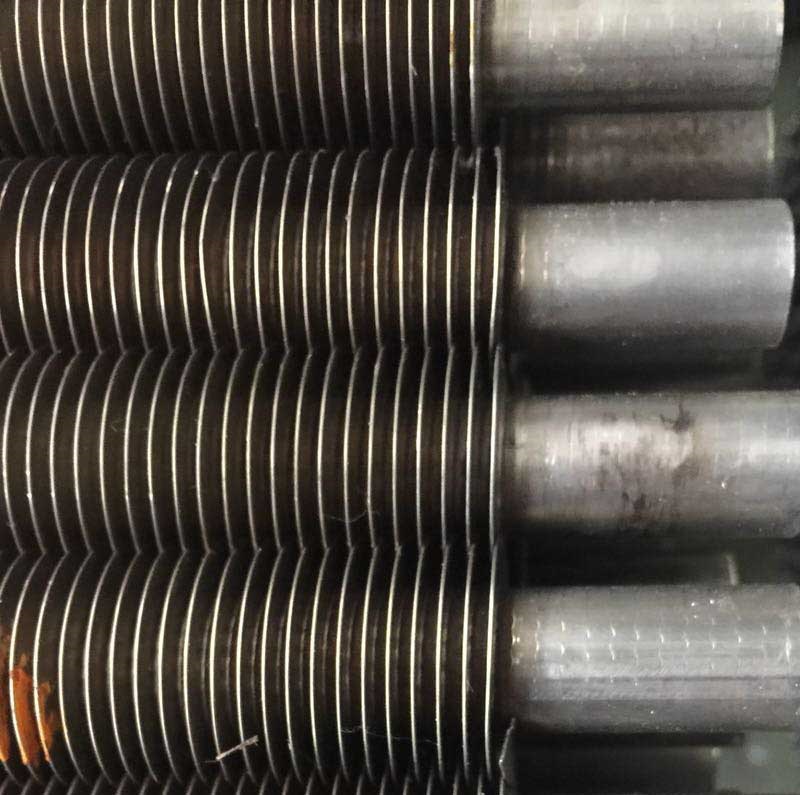

ASTM A1012 Seamless and Welded Austenitic Stainless Steel Condenser and Heat Exchanger Tubes With Integral Fins

seamless and welded ferritic, austenitic and duplex alloy steel tubing on which the external or internal surface, or both, has been modified by a cold forming process to produce an integral enhanced surface for improved heat transfer. The tubes are used in surface condensers, evaporators, heat exchangers and similar heat transfer apparatus in unfinned end diameters up to and including 1 in. (25.4 mm). Boiler tubes are excluded.

Integral Fins Tube Manufacture

The integrally enhanced (finned) tubes shall be manufactured from seamless, welded, or welded/cold worked plain tubes that conform to one of the following ASTM specifications: A213/A213M, A249/A249M, A268/A268M, A269, A688/A688M, A789/A789M, A803/A803M.

Finished tubes shall be clean and free of foreign material, shall have smooth ends free ofburrs, and shall be free of injurious external and internal imperfections. A slight amount of oxidation on the surface resulting from heat treatment after enhancing or bending is acceptable. When the plain tube specification allows for a slight amount of oxidation on the surface resulting from heat treatment, this also is acceptable.

Integral Fins Tube Chemical Composition

| Grade | UNS | Carbon | Manganese | Phosphorous | Sulfur | Silicon | Chromium | Nickel | Molybdenum | Nitrogen | Copper |

| TP 201 | S20100 | 0.15 | 5.50–7.5 | 0.06 | 0.03 | 1 | 16.0–18.0 | 3.5–5.5 | … | 0.25 | … |

| TP 202 | S20200 | 0.15 | 7.5–10.0 | 0.06 | 0.03 | 1 | 17.0–19.0 | 4.0–6.0 | … | 0.25 | … |

| TPXM-19 | S20910 | 0.06 | 4.0–6.0 | 0.045 | 0.03 | 1 | 20.5–23.5 | 11.5–13.5 | 1.50–3.00 | 0.20–0.40 | … |

| TPXM-29 | S24000 | 0.08 | 11.5–14.5 | 0.06 | 0.03 | 1 | 17.0–19.0 | 2.3–3.7 | … | 0.20–0.40 | … |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | … | … | … |

| TP304L | S30403 | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–12.0 | … | … | … |

| TP304H | S30409 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | … | … | … |

| … | S30415 | 0.04–0.06 | 0.8 | 0.045 | 0.03 | 1.00–2.00 | 18.0–19.0 | 9.0–10. | … | 0.12–0.18 | … |

| TP304N | S30451 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | … | 0.10–0.16 | … |

| TP304LN | S30453 | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 8.0–11.0 | … | 0.10–0.16 | … |

| TP305 | S30500 | 0.12 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 11.0–13.0 | … | … | … |

| … | S30615 | 0.16–0.24 | 2 | 0.03 | 0.03 | 3.2–4.0 | 17.0–19.5 | 13.5–16.0 | … | … | … |

| … | S30815 | 0.05–0.10 | 0.8 | 0.04 | 0.03 | 1.40–2.00 | 20.0–22.0 | 10.0–12.0 | … | 0.14–0.20 | … |

| TP309S | S30908 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–15.0 | … | … | … |

| TP309H | S30909 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–15.0 | … | … | … |

| TP309Cb | S30940 | 0.08 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–16.0 | … | … | … |

| TP309HCb | S30941 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 22.0–24.0 | 12.0–16.0 | … | … | … |

| TP310S | S31008 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0–26.0 | 19.0–22.0 | … | … | … |

| TP310H | S31009 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 24.0–26.0 | 19.0–22.0 | … | … | … |

| TP310Cb | S31040 | 0.08 | 2 | 0.045 | 0.03 | 1 | 14.0–26.0 | 18.0–22.0 | … | … | … |

| TP310HCb | S31041 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 24.0–26.0 | 19.0–22.0 | … | … | … |

| … | S31050 | 0.03 | 2 | 0.03 | 0.015 | 0.4 | 24.0–26.0 | 21.0–23.0 | 2.00–3.00 | 0.10–0.16 | … |

| … | S31254 | 0.02 | 1 | 0.03 | 0.01 | 0.8 | 19.5–20.5 | 17.5–18.5 | 6.0–6.5 | 0.18–0.25 | 0.50–1.00 |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | … | … |

| TP316L | S31603 | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | … | … |

| TP316H | S31609 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 | … | … |

| TP316N | S31651 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–13.0 | 2.00–3.00 | 0.10–0.16 | … |

| TP316LN | S31653 | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.0–18.0 | 10.0–13.0 | 2.00–3.00 | 0.10–0.16 | … |

| TP317 | S31700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 11.0–15.0 | 3.0–4.0 | … | … |

| TP317L | S31703 | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 11.0–15.0 | 3.0–4.0 | … | … |

| … | S31725 | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.0–20.0 | 13.5–17.5 | 4.0–5.0 | 0.2 | … |

| … | S31726 | 0.03 | 2 | 0.045 | 0.03 | 1 | 17.0–20.0 | 14.5–17.5 | 4.0–5.0 | 0.10–0.20 | … |

| … | S32050 | 0.03 | 1.5 | 0.035 | 0.02 | 1 | 22.0–24.0 | 20.0–23.0 | 6.0–6.8 | 0.21–0.32 | 0.4 |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | 0.1 | … |

| TP321H | S32109 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | 0.1 | … |

| … | S32654 | 0.02 | 2.0–4.0 | 0.03 | 0.005 | 0.5 | 24.0–25.0 | 21.0–23.0 | 7.0–8.0 | 0.45–0.55 | 0.30–0.60 |

| … | S33228 | 0.04–0.08 | 1 | 0.02 | 0.015 | 0.3 | 26.0–28.0 | 31.0–333.0 | … | … | … |

| … | S34565 | 0.03 | 5.0–7.0 | 0.03 | 0.01 | 1 | 23.0–25.0 | 16.0–18.0 | 4.0–5.0 | 0.40–0.60 | … |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | … | … |

| TP347H | S34709 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | … | … |

| TP348 | S34800 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | … | … |

| TP348H | S34809 | 0.04–0.10 | 2 | 0.045 | 0.03 | 1 | 17.0–19.0 | 9.0–12.0 | … | … | … |

| … | S35045 | 0.06–0.10 | 1.5 | 0.045 | 0.015 | 1 | 25.0–29.0 | 32.0–37.0 | … | … | 0.75 |

| TPXM-15 | S38100 | 0.08 | 2 | 0.03 | 0.03 | 1.50–2.50 | 17.0–19.0 | 17.5–18.5 | … | … | … |

| … | S38815 | 0.03 | 2 | 0.04 | 0.02 | 5.5–6.5 | 13.0–15.0 | 15.0–17.0 | 0.75–1.50 | … | 0.75–1.50 |

| … | N08367 | 0.03 | 2 | 0.04 | 0.03 | 1 | 20.0–22.0 | 23.5–25.5 | 6.0–7.0 | 0.18–0.25 | 0.75 |

| … | N08926 | 0.02 | 2 | 0.03 | 0.01 | 0.5 | 19.0–21.0 | 24.0–26.0 | 6.0–7.0 | 0.15–0.25 | 0.50–1.50 |

| … | N08904 | 0.02 | 2 | 0.04 | 0.03 | 1 | 19.0–23.0 | 23.0–28.0 | 4.0–5.0 | 0.1 | 1.00–2.00 |

Integral Fins Tube Temper

The tube after enhancing shall normally be supplied in the as-finned temper. When specified by the purchaser, for bending, coiling or other fabricating operations, enhanced portions of the tube may be stress relief annealed or solution annealed.

Heat treatment of enhanced sections, or bend areas, or both, shall be in accordance with the governing plain tube specification.

Integral Fins Tube Ends

Tubes described by this specification shall be furnished with unenhanced (plain) ends.

Integral Fins Tube Packaging and Package Marking

The tube shall be packaged in accordance with the manufacturer’s standard practice, unless otherwise agreed upon between the manufacturer and the purchaser and so stated in the purchase order.

Each shipping unit shall be legibly marked with the name of the supplier, name of the customer, ship to address, purchase order number, alloy designation, size or part number, tube length and number of pieces.

Integral Fins Tube Ordering Information

Welded or seamless;

Alloy grade and UNS designation;

Dimensions; plain tube outside diameter, plain tube wall thickness (average or minimum specified), length and location of unenhanced surfaces and the total tube length.

Configuration of enhanced surfaces (fins per unit length, fin height, wall thickness under fin, rib pitch, rib height, etc.) shall

be as agreed upon between the manufacturer and purchaser

Temper (as-finned or stress relief annealed);

Quantity;

Packaging;

Nondestructive tests;

Customer inspection;

Mill test report;

Certification.

Other Services

1 Cutting: Small pieces

2 End: Plaint or Beveled or threaded

3 CNC Machine: Produce as your drawing

4 Package: Bare/Nylon/Canvas/Wooden

5 Payment:T/T, L/C, O/A(request credit)

6 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Contact Fushun Integral Fins Tube Today

Contact us for more information regarding precision steel tubing specifications and product options, or request a quote for further pricing details today.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.