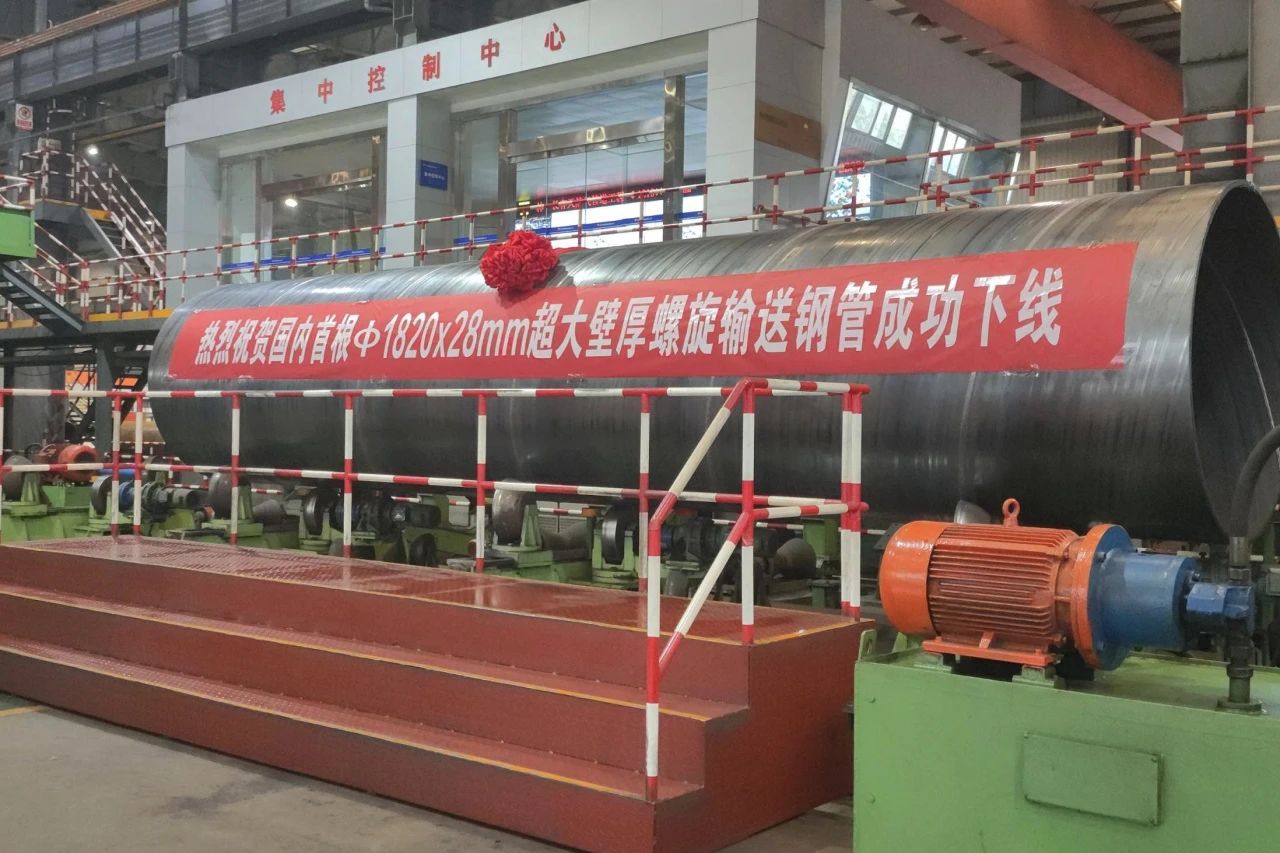

On August 25, 2024, it was announced that the super-large thick-walled spiral submerged arc welded steel pipe with a diameter of 1820mm and a wall thickness of 28mm, trial-produced by China Steel Pipe Company, passed the appraisal of the National Engineering Technology Research Center for Oil and Gas Pipeline Materials. Experts unanimously agreed that this new product demonstrates high technical level and strong innovation, with overall achievements reaching China’s leading standards, marking the successful trial production of China’s largest thick-walled spiral transmission pipe.

On August 25, 2024, it was announced that the super-large thick-walled spiral submerged arc welded steel pipe with a diameter of 1820mm and a wall thickness of 28mm, trial-produced by China Steel Pipe Company, passed the appraisal of the National Engineering Technology Research Center for Oil and Gas Pipeline Materials. Experts unanimously agreed that this new product demonstrates high technical level and strong innovation, with overall achievements reaching China’s leading standards, marking the successful trial production of China’s largest thick-walled spiral transmission pipe.

This spiral transmission pipe was custom-developed by China Steel Pipe Company for civilian water supply projects, primarily used for pipe jacking operations at construction sites. Compared to traditional jacking pipes, the large thick-walled spiral steel pipe features shorter welds, higher geometric dimensional accuracy, and superior weld performance, providing new equipment and solutions for construction.

The project demanded a wall thickness of up to 28mm, while the maximum wall thickness of similar domestic products does not exceed 26mm, posing significant production challenges. To address this, the steel pipe company actively communicated with raw material manufacturers to collaboratively complete custom material production. They overcame technical control difficulties in coiling, shape control, and dimensional performance during the production of ultra-thick hot-rolled steel coils, meeting the raw material requirements for customized production of 28mm thick-walled transmission pipes. Additionally, to solve technical issues such as extreme forming stress on ultra-thick steel strips and weld crack defects, the company intensified scientific research during production. The technical team conducted in-depth analysis and evaluation of welding equipment in advance and carried out adaptive modifications. Through optimizing forming control data, conducting welding process matching tests, and optimizing welding parameters, they effectively improved the appearance quality and internal weld performance of the transmission pipes.

The company completed all production preparations in just 15 days and successfully trial-produced the 1820mm diameter, 28mm wall thickness spiral transmission pipe within 16 hours. Tests showed that the geometric dimensions and weld performance of the spiral transmission pipe met standards and were widely recognized by customers. The successful trial production of China’s largest thick-walled spiral transmission pipe not only enriches the specification catalog and application scenarios of large-diameter transmission pipe products but also provides a new tool for Chinese petroleum enterprises to complete civilian projects with high quality.

Leave A Comment