Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

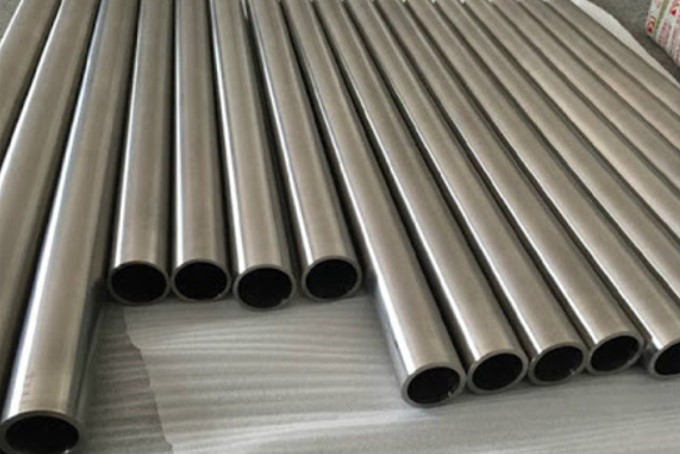

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products. Produced from hot rolled 1026, the cold drawing process increases the tube’s physical properties and offers better tolerances and reduced machining allowances over hot finish seamless. Cold drawn seamless tubing possesses a high strength-to-weight ratio and can be processed to provide a combination of desired characteristics: dimensional accuracy; good surface quality; excellent micro-structure uniformity; good machinability; and high tensile properties. It is also suited for such post-treatments as carburizing and heat treating.

Cold drawn seamless mechanical tubing is employed in a variety of uses, particularly when heavy wall thicknesses, specific steel alloys or both are required. Specific applications include bushings, spacers, bearings and other mechanical parts in automobiles, trucks, aircraft and construction, agricultural and drilling equipment, as well as hydraulic cylinders.

Benefits Of Cold Drawn Seamless Tubing

Higher Strength & Hardness Properties

Size Accuracy

Enhanced Appearance

Uniform Micro-structure

Easier To Machine

Superior Finish In Subsequent Manipulations

1018 Steel Tube

1018 is a free machining grade and is among the most commonly available grades in the world. Alloy 1018 is easily formed, machined, welded and fabricated. Cold drawn tubing inherently possesses a high strength-to-weight ratio and can be processed to provide a combination of desired characteristics: good surface quality, excellent micro-structure uniformity, good machinability and high tensile properties. Seamless mechanical tubing is produced from solid round billets by rotary piercing and then is rolled in an Assel mill equipped with a no-end-loss unit that permits an extremely broad range of diameter/wall thickness ratios. Tubes are then processed through a multiple-pass sizing reducing mill and a rotary sizer. The 1018 Cold Drawn Seamless Tube listed for sale on this page is Pickled & Oiled and offered in a black, unground state. We additionally offer this material with a ground and polished finish. 1018 Cold Drawn Seamless Tube is the primary tubular steel used in the manufacturing of Race Cars in the NASCAR racing series.

APPLICATIONS

- Hydraulic Cylinders

- Auto and Truck Axles

- Suspension parts and shock absorbers

- High Speed Shafts and rollers

- Bearings and Spacers

- Roll cages

- Agricultural components and many other machined tubular parts.

Standards

- ASTM A519 Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

- EN10305 Steel Tubes for Precision Applications Seamless Cold Drawn Tubes

- DIN 2391-1-2 seamless precision tubes

- BS EN 6323 part 4 specific requirements for cold finished seamless steel tubes

- JIS G 3444 Carbon steel tubes for general structure

- JIS G 3445 Carbon steel tubes for machine structure

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming. (e.g. bending, expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Drawing Process

Floating/Drawing process of pulling a metal bar, rod, or wire through the whole of a die to alter its finish, shape, size, and/or mechanical properties. The tube drawing technique reduces the outer diameter, inner diameter, and wall thickness of the tube. The integrity of the surface of the tube is maintained, ideal for stainless steel tubes.

Annealing Process

Annealing is used to soften the metal before further cold working or fabrication processes, and improves the overall metallurgical microstructure of the tube. During tube reduction or cold drawing, it can become hard and somewhat brittle. To be able to draw the tube again, stresses formed during cold working need to be removed to return the material to its normal state.

During annealing the tube is heated to a controlled temperature (up to 2100°F) and soak time. Through this process the tube remains in shape, but the grains in the structure of the tube reform into a regular unstressed pattern. The resulting annealed tube is softer and suitable for redrawing.

Manufacturing process

Tubular Products seamless mechanical tubing is produced from solid round billets by rotary piercing and then rolled in an Assel mill that permits an extremely broad range of diameter/wall thickness ratios. Tubes are then processed through a multiple-pass size reducing mill and a rotary sizer.

Tube lengths from the hot mill are slowly air cooled or moved directly to a unique is othermal annealing furnace to ensure a uniform microstructure hardness to promote excellent machinability. This process contrasts with conventional slow-cool furnaces, where tubes are cooled in bundles. That can result in variations in microstructure and hardness from tube to tube and even within a tube itself.

After cooling, tubes are pickled in an acid bath to remove mill scale and inspected. Minor imperfections are removed by grinding prior to cold drawing and additional processing. During the cold drawing process, tubes are drawn in a controlled fashion over a mandrel and through a die to reduce the diameter and wall thickness. After forming and depending on customer requirements, the tubing is stress relief annealed, straightened and cut to length. Tubes are inspected for dimensional accuracy and surface finish.

Cold working, applied to both inside and outside surfaces, improves surface finish, increases tensile properties, improves machinability in many grades and results in more precise dimensions. Outside diameter and wall thickness tolerance are improved by approximately 50 percent.

Packaging

Straight lengths of seamless tubing can be individually sleeved in paper or plastic and/or packaged in our unique cardboard spacers to ensure no damage occurs during transit. Coiled seamless tubes are horizontally packed using paper or cardboard separators to prevent tube-to-tube contact. All tubing is packed in either wooden crates lined with wax craft paper, tri-wall clay-coated reinforced cases, or standard cardboard boxes. Plastic end caps that prevent foreign material from getting inside the tubes are also available upon request.

Other Services

1 Cutting: Small pieces

2 End: Plaint or Beveled or threaded

3 CNC Machine: Produce as your drawing

4 Package: Bare/Nylon/Canvas/Wooden

5 Payment:T/T, L/C, O/A(request credit)

6 Transport:FOB/CFR/CIF/DDU/DDP (train/ship/Air)

Contact Fushun for CDS Steel Tubing Today

Contact us for more information regarding precision steel tubing specifications and product options, or request a quote for further pricing details today.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.